System types:

CorroDec®2G offers a wide variety of sensor types, expansion modules, installation options, and interrogation paths.

It is, therefore, suitable for almost all types of structures (new or existing).

The sensors are passive, energy-free, and have no cable connection to the outside world. In this way, we ensure an extremely long service life for the sensors and rule out the possibility of harmful factors entering the structure along a cable leading to the outside.

Sensor types:

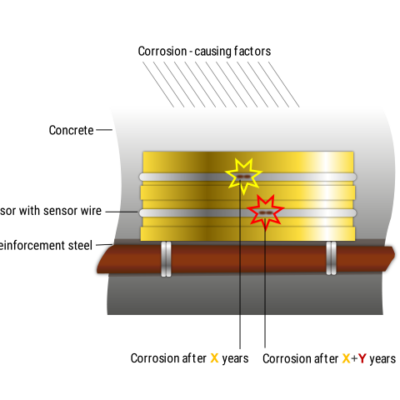

The CorroDec®2G corrosion sensor is placed over the reinforcing steel before or after concreting. A special sensor wire is routed around the sensor body, which is destroyed by corrosive influences. For the operator of this monitoring system, the following information is available after a query with the wireless reader:

- Sensor wire 1st level OK yes/no

- Sensor wire 2nd level OK yes/no

- Temperature in concrete

Special corrosion sensors are available for concrete structures up to 25m thick. A reader receives the data from the sensors at any time, before, during, and after the concreting process. An optional remote query is also possible without being on-site.

The moisture sensor is used to measure the electrical conductivity and temperature within the concrete. The results are a referenced humidity value as a function of temperature that allows us to understand the concrete moisture profile over its life cycle which can alert us of irregularities in real time.

Special moisture sensors are available for concrete structures up to 25m thick. A reader gear receives the data from the sensors at any time, before, during, and after the concreting process. An optional remote query is also possible without being on-site.

Remote reading for non-easily accessible areas is possible!

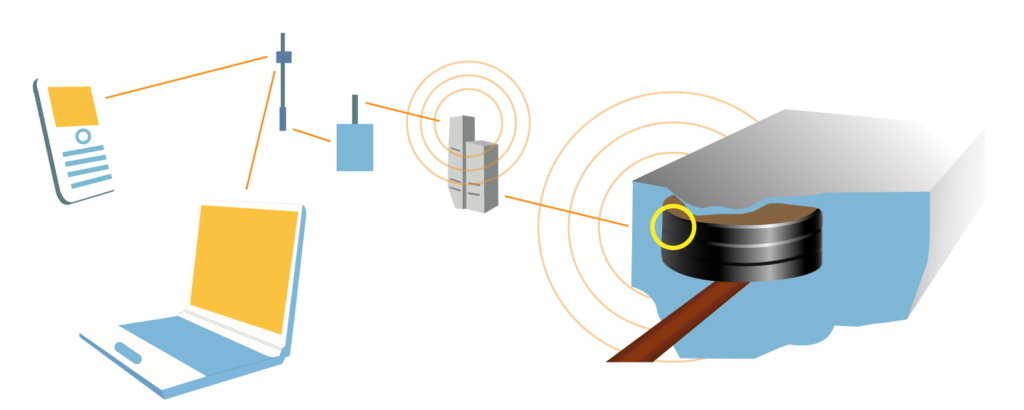

Our sensors allow remote reading with the help of our extension system.

Depending on the installation scenario, the standard reading range between reader and sensor of 1.5 inch (40cm) may not be sufficient.

For this purpose, we have developed an external sensor antenna connected to the sensor unit by cable to extend its signal to a range of up to 80 ft (25m).

Even in cases where the sensors are in inaccessible places (e.g., in the middle of the roadway, foundations, bridge substructure, etc.), convenient reading is possible without additional effort and at a safe, easily accessible location.

This eliminates the need for time-consuming and dangerous lane closures or special crane operations, e.g., inspection. Even in the area of hydraulic structures, a readout is possible “on dry feet.”

The CorroDec®2G sensors:

- Increased Sustainability & Durability

- Allows Effective Lifecycle Monitoring

- Affordable 24/7 monitoring and Data Transfer

- Reduced Repair & Maintenance Costs

- Reduced Physical Inspections Costs – remote monitoring.

- Increased Safety

- 24/7 monitoring using NB-IoT – this enables remote monitoring.

- Predictive Maintenance

Query types:

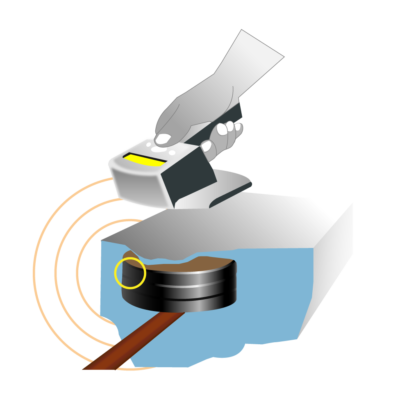

Our sensors are passive and require no direct energy source unlike many others on the market. Its power is induced from the outside (unique in the field) via a gateway or a handheld reader.

After placing the sensors, the status of the system (self-test) and the sensor wire are evaluated fully automatically and signaled to the reader.

The data that is read out on-site* is automatically transmitted in real time to our InfrastructureTek Data Hub for tracking and analyzing purposes and display in dashboards and customized reports.

*The reading range depends on the type of reader used (standard reader: up to 0.4 inch (10cm) / advanced reader: up to 1.5 inches (40cm)). In addition, our external antenna unit can be used for greater installation depths, enabling installations up to 80 ft (25 m).

As an alternative to on-site reading, the sensors can be queried with the help of the system extension for remote reading, which is attached to the structure within the reading range.

The data is automatically transmitted via our “I-Tek-Universal Monitoring System” and can be visualized on our dashboards and reports or directly connected to an existing internal monitoring system. This means that the structure’s condition at the neuralgic points can be called up remotely at any time.

Installation types:

- Installation of the corrosion sensor above the reinforcement (corrosion attack from above) prior to concrete placement.

A minimum concrete cover of 0.6 inch (15 mm) from the upper edge of the sensor must be observed for quality of C20/25. For higher concrete strength classes from C40/45, the value can be reduced by 5 mm.

Fastening of the corrosion sensor underneath/behind the reinforcement (determination of the effect of, e.g., remaining chloride-contaminated concrete after repair = corrosion attack from below). The sensor itself is to be embedded in a coupling mortar, after which the repair site is closed in accordance with the recognized technology rules (e.g., with plastic-modified mortar).

Fixing of the sensor by means of a core hole drilling, filling with coupling mortar, and finishing (depending on the position) with a mechanical sealing system or shrinkage-free plastic-modified mortar. The subsequent mechanical load situation and the corresponding after-treatment of the surface must be observed in accordance with the current regulations. In the case of a final coating, the coupling mortar can be applied to the surface.

Tell us about your project

Get in touch with us to share your needs and project requirements. We're happy to help!