Our infrastructure must meet performance requirements such as strength, stability, and durability. Achieving these requirements will have a lasting effect on our mobility in the future.

Concrete is the most widely used construction material due to its inherent strength and because it can be beautifully molded to combine form with function. However, external environmental influences such as moisture and chlorides can cause internal damage that cannot be detected from the outside of the structure at early stages.

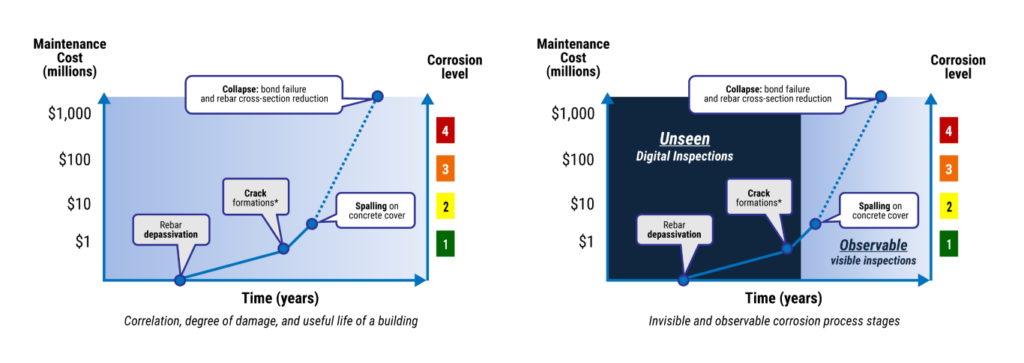

The detection of corrosion inside the concrete structure, at an early stage, determines the costs for its maintenance and future repair.

Implementing SHM systems is a step forward toward proactive maintenance systems. Existing maintenance protocols are generally based on a reactive strategy; it means that repairs and interventions are usually performed when damage has already happened. SHM systems can help identify and quantify these structural defects in the early stages, when repair and rehabilitation will be more cost-effective, and more efficient.

Value preservation, safety, and sustainability through NB-IoT early damage detection

Traditional condition assessments are popular but unfortunately, are labor intensive and they are typically based on visible and non-destructive testing methods that have very limited success in detecting early corrosion activity.

Because the rebar corrosion process causes the concrete structure to die from the inside out, there could be more than a 10-fold increase in rehabilitation costs between early stage detection and later detection when corrosion activity is manifest by outward evidence such as cracking and/or spalling of the concrete.

CONCRETE CORROSION MONITORING

Concrete Know-How from the inside-out

Reinforced concrete allows for the design of elegant structural shapes that are economically efficient with superior strength; however, such structures are not immune from deterioration.

Reinforcement corrosion is one of the major deterioration mechanisms of reinforced concrete structures worldwide and is by far the biggest durability issue for reinforced concrete. Once the corrosion begins, it will spread when left untreated jeopardizing the safety of the structure and its tenants.

OUR SOLUTION:

CORRODEC®2G

REAL-TIME READINGS TO PREVENT FUTURE DAMAGE

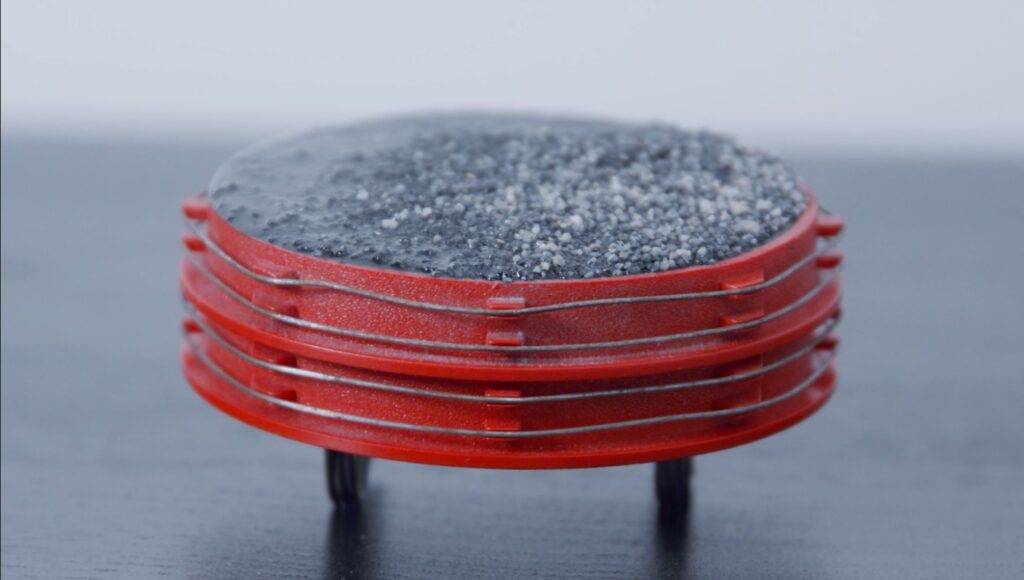

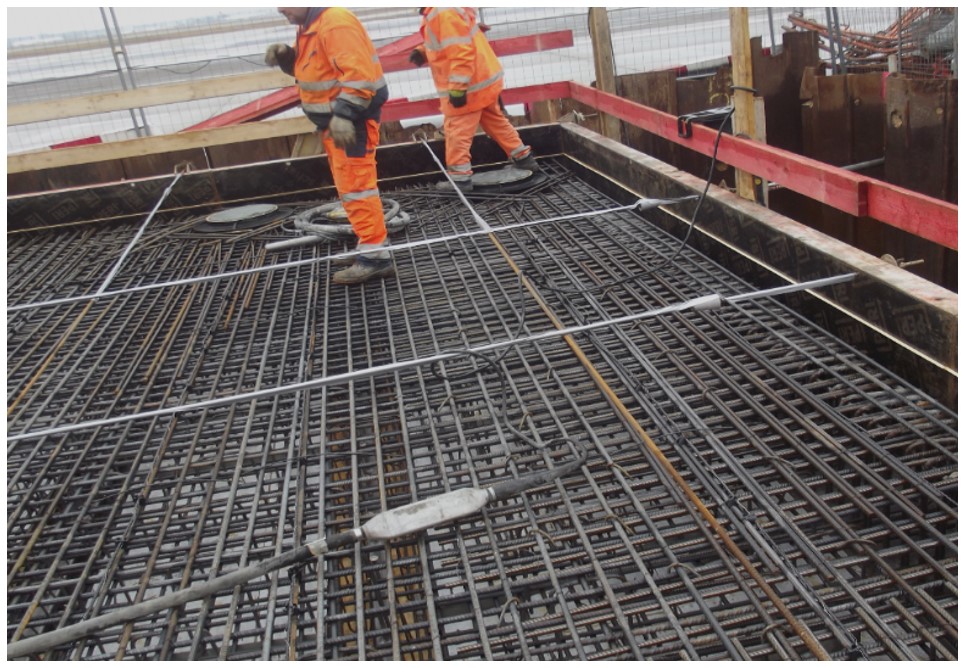

Using the latest technology, InfrastructureTek’s “hockey puck” size corrosion and humidity sensors are a unique early warning system that offers a simple and cost-effective solution when placed at the vulnerable points of the structure.

Our wireless sensors, which require no batteries or external wires, automatically monitor the structure’s internal health long before damage manifests in costly and disruptive rehabilitation.

- Simple operation & evaluation

- Wireless & Powerless

- Remotely accessible

- Retrofittable

How does it work?

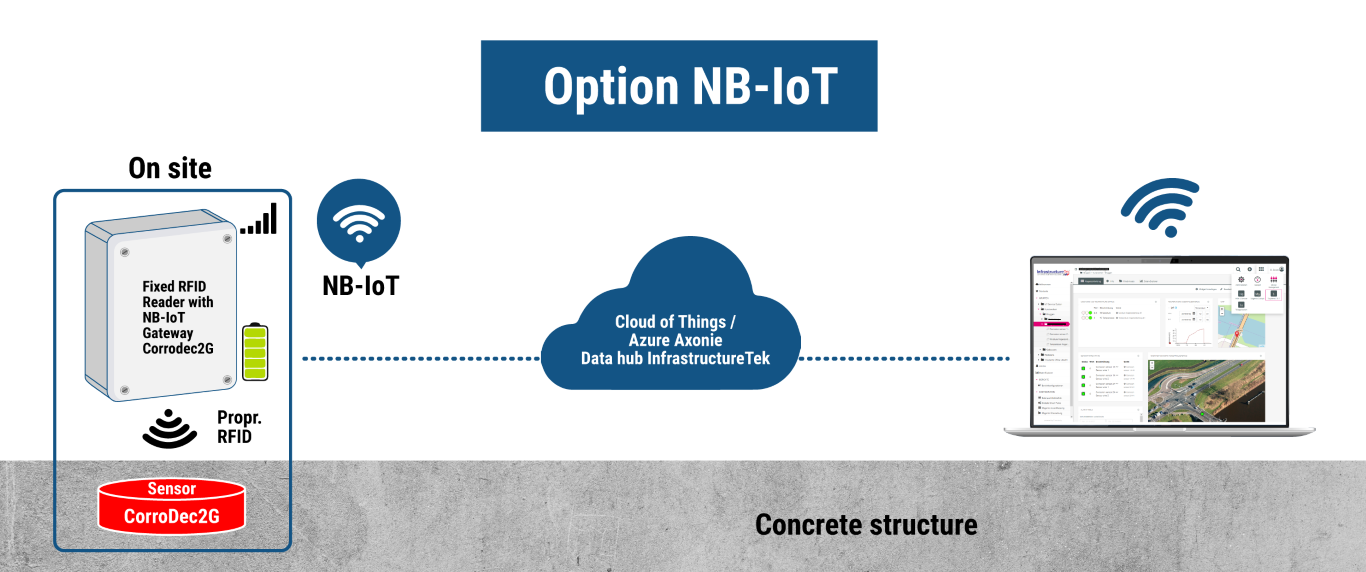

Our sensors are passive and require no direct energy. It is power induced from the outside via a gateway or a handheld reader. Once the sensors are fully embedded within the concrete, it automatically transmits via our “I-Tek- Universal Monitoring System” to our Data Hub.

Data can be read out on-site or can be queried with the help of the system extension for remote reading. After processing the data, it is analyzed and displayed in dashboards and customized reports on the I-Tek’s monitoring platform.

Where can the sensors be installed?

NEW or EXISTING Bridges, multi-story parking garages, buildings, tunnels, stadiums, pre-stressed/ post-tensioned structures, and more…

Why Corrode®2G

STRUCTURAL VULNERABILITY ASSESSMENT

- Simple operation & evaluation

- Wireless & Powerless

- Remotely accessible

- Monitors the structure’s health

- More control over maintenance and repair costs

- Can be used in new and existing structures

- Online monitoring via a proprietary gateway using cost-efficient NB-IoT technology

- Web-based visualization of measured data with alarm capabilities

HASLE-FREE, COST-EFFECTIVE, AND FLEXIBLE

Tell us about your project

Get in touch with us to share your needs and project requirements. We're happy to help!