Tunnel Restoration

| Project | Tunnel Rehabilitation Project |

|---|---|

| Location | Germany |

| Date | July 2014 |

| Client | State Contracting Authority/ State Enterprise |

Initial Situation

As a result of operational retrofitting work, the operators of the motorway tunnel detected chlorides in the portal area, which made it necessary to rehabilitate the concrete of the tunnel walls.

The rehabilitation aimed to reduce the costs of the necessary repair measures and to observe the residual risk (chlorides remaining in the structure) and the effectiveness of the surface protection systems used over a very long period.

Solution

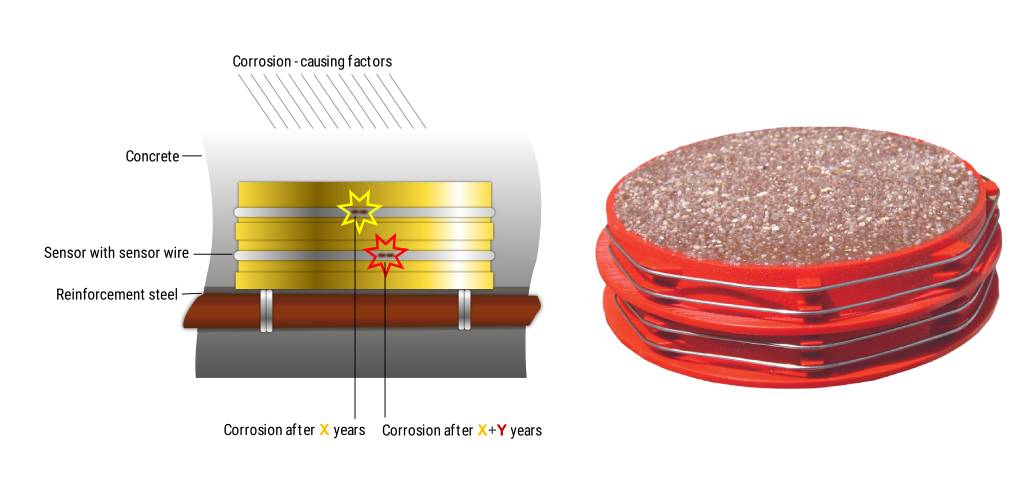

Installation of a monitoring system that evaluates and prevents a potential residual risk after the gradual removal of the chloride-contaminated concrete layer, and at the same time, to evaluate the effectiveness of the surface protection in the long run.Installation of a monitoring system that evaluates and prevents a potential residual risk after the gradual removal of the chloride-contaminated concrete layer, and at the same time, to evaluate the effectiveness of the surface protection in the long run.

Corrodec©2G sensors, a cable- and energy-free corrosion and moisture monitoring system, were installed in the portal tunnel areas to ensure the safety of the structure.

The data was read out manually using a hand-held reader and remotely (via GPRS) to visualize the information. The status of the sensors can thus be queried remotely at any time.

In addition, the condition of the sensors can be determined directly on-site by means of a hand-held reader within the scope of the maintenance intervals customary for the building.

Added Value

- Uncomplicated visualization of the building condition

- Significant cost reduction in subsequent concrete repair due to early detection of damage

- Sustainable safeguarding of investments

- Proof of construction quality

- Differentiated repair in case of OS system failure

- Targeted control of the inspection intervals by querying the humidity values

- Reduced blocking times for subsequent repairs